MIL-I-50412 (MU)

4.3

Inspection provisions

4.3.1

Lot formation

4.3.1.1 Parts . -A lot of' inner sleeves, outer cups, or front

supports shall consist of parts produced by one manufacturer In

one unchanged process in accordance with the same drawing, and

same drawing revision, same specification and same specification

revision. Drawing, specification, and process changes not affecting

safety. performance or interchangeability , as determined by the

Government, shall not necessitate changing the lot interfix number.

The criteria and Procedures for the assignment of inspection lot

interfix numbers shall be in accordance with Standard MIL-STD-1168.

4,3.1.2 Bridge ribbons. -A lot shall consist of all bridge

ribbons produced by one manufacturer to the same drawings, same

drawing revision, same specification, and same specification revi-

sion using the same punch and die and stamped from one continuous

roll of preformed ribbon which has been certified by the supplier

as complying with the applicable material standard. The criteria

and procedures for the assignment of Inspection lot interfix numbers

shall be In accordance with MIL-STD-1168.

4.3.2 Examination. -Sampling plans and procedures for the

following classifications of defects shall be in accordance with

Standard MIL-STD-105 except that inspection for critical defects,

hen listed, shall be 100 percent. Also, at the option of the

procuring activity, AQL's and sampling plans may be applied to

the individual characteristics listed using an AQL of 0.40 percent

for each major defect and an AQL of 0.65 percent for each minor defect.

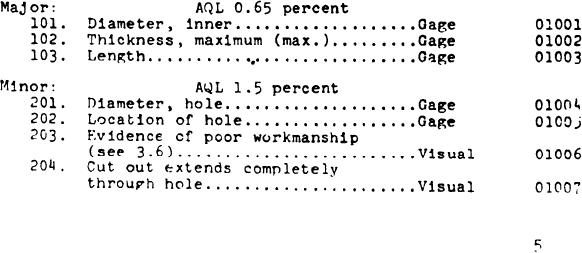

4.3.2.1 Cup, outer (see drawing 9204178 covering a detail of

drawing 9204185).

Defects

Categories

Method of

Code No.

Inspection

(see 6.2)

Critical:

None defined.

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business